The Scale of the Crisis is Staggering

The numbers paint a sobering picture of America’s workforce reality. The Manufacturing Institute projects that 2.1 million manufacturing jobs could remain unfilled by 2030 due to the skilled worker shortage. In construction, 91% of firms are struggling to find qualified workers according to the Associated General Contractors of America. But here’s what those statistics really mean for your business: longer wait times for critical repairs, higher service costs, and increased risk of system failures that could shut down your operations entirely.

Consider this: there were 584,000 job openings in US manufacturing in January 2024 alone, with

welders representing one of the most critical shortages. Since 70% of all manufactured products require

welding skills, this single trade shortage affects virtually everything your business relies on, from

HVAC equipment to fire safety systems.

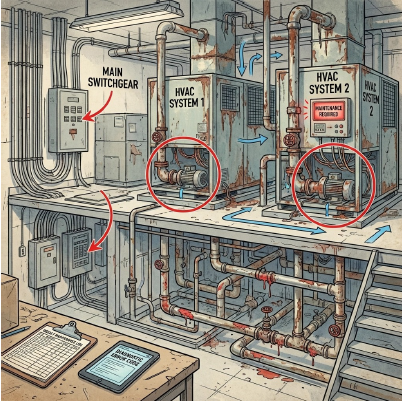

Your Daily Operations Are Already Feeling the Impact

Emergency Repairs Take Longer

When your HVAC system fails on the hottest day of summer, you’re not just competing with other

businesses for service: you’re competing for a shrinking pool of qualified technicians. What used to

be a same-day repair might now take days or even weeks, depending on the complexity and availability

of skilled workers.

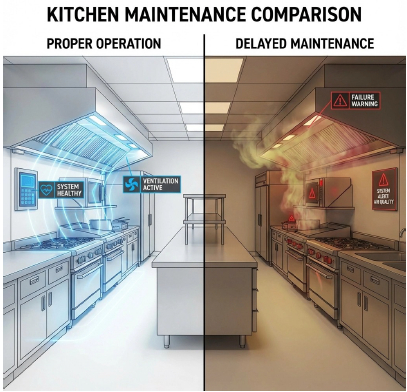

Preventive Maintenance Gets Delayed

The shortage forces many contractors to prioritize emergency calls over routine maintenance. This

creates a dangerous cycle: systems that should receive regular attention are pushed to the back of

the queue, making catastrophic failures more likely and more expensive when they occur.

Quality Control Suffers Under Pressure

Overworked technicians handling more jobs than they can manage properly leads to rushed work

and overlooked details. The remaining employees take on more responsibilities, leading to burnout

and compromised quality control that could affect your systems’ longevity and safety.

The Ripple Effect Hits Every Industry

The skilled trades shortage doesn’t respect industry boundaries. Manufacturing faces production delays

when equipment breaks down and qualified repair technicians aren’t available. Retail operations

lose customers when HVAC failures create uncomfortable shopping environments. Healthcare facilities

face serious compliance issues when critical systems can’t be maintained properly.

Real Estate and Property Management

Property values suffer when building systems can’t be properly maintained. Tenant satisfaction drops

when repairs take weeks instead of days. New construction projects face delays that cascade into financing

complications and lease agreement issues.

Food Service and Hospitality

Restaurant kitchen exhaust systems that can’t be cleaned on schedule create fire hazards and health

code violations. Hotels with unreliable HVAC systems face guest complaints and negative reviews that

damage their reputation permanently.

Education and Healthcare

Schools and hospitals can’t simply close when systems fail. They’re forced to pay premium rates for

emergency services or operate with compromised environmental conditions that affect learning outcomes

and patient safety.

The Hidden Costs Are Eating Your Budget

The skilled labor shortage creates a perfect storm of escalating costs that many facility managers

don’t see coming until it’s too late.

Wage Inflation is Permanent

Average weekly earnings for construction and manufacturing roles are now 23.5% and 20.1% above

pre-COVID levels respectively. These wage increases become your service cost increases, and unlike

temporary price spikes, wage inflation tends to be permanent.

Emergency Service Premiums

When you can’t get routine maintenance, everything becomes an emergency. Emergency service calls

typically cost 150-200% more than scheduled maintenance visits, and you’re paying these premiums

more frequently as systems fail unexpectedly..

Extended Downtime Costs

The true cost isn’t just the repair bill: it’s the lost productivity, unhappy customers, and potential safety

violations while you wait for qualified technicians. A restaurant that can’t operate its kitchen exhaust

system isn’t just paying for repairs; it’s losing daily revenue until the system is fixed.

Long-Term Consequences Are Building

This isn’t a temporary disruption that will resolve itself. The skilled trades shortage reflects decades of

underinvestment in vocational training and a cultural shift toward four-year college degrees over

hands-on technical careers.

Aging Workforce with No Replacements

Many skilled tradespeople are approaching retirement age, and there simply aren’t enough young

workers entering these fields to replace them. The average age of workers in many trades continues

to rise, creating a demographic time bomb.

Technology Gap Widens

Modern commercial systems are increasingly complex, requiring workers who understand both traditional

mechanical skills and digital control systems. The shortage of workers with these hybrid skill

sets will only worsen as technology advances.

Infrastructure Investment Can’t Be Realized

The Bipartisan Infrastructure Law allocates billions for infrastructure improvements, but without

skilled workers to do the work, these investments can’t translate into actual improvements in your

community’s commercial infrastructure.

What Facility Managers Must Do Now

Don’t wait for this crisis to hit your operations directly. Smart facility managers are already adapting

their strategies to work within the new reality of skilled labor scarcity.

Prioritize Preventive Maintenance

Regular maintenance isn’t optional anymore: it’s your primary defense against catastrophic failures

when emergency help might not be available for days or weeks. Work with contractors who prioritize

scheduled maintenance customers and build long-term relationships.

Build Relationships with Multiple Contractors

Relying on a single contractor for critical systems is risky when that contractor might not have available

technicians when you need them. Develop relationships with multiple qualified service providers

to ensure you have options during emergencies.

Invest in System Monitoring

Modern monitoring systems can identify potential problems before they become emergencies, giving

you more time to schedule repairs when technicians are available rather than being forced into emergency

service situations.

Budget for Higher Service Costs

Factor the new reality of higher labor costs into your facility budgets. The days of assuming service

costs will remain stable year over year are over.

The Bottom Line for Your Business

The skilled trades shortage isn’t someone else’s problem: it’s already affecting your operations, your

costs, and your ability to maintain the comfortable, safe environment your business depends on.

Every day you wait to adapt your maintenance strategy is another day closer to an emergency that

could shut down your operations when qualified help isn’t available.

The businesses that will thrive in this new environment are those that recognize the reality early and

build relationships with contractors who understand how to work efficiently in a labor-constrained

market. Don’t let the skilled trades shortage catch you unprepared.

At Pronto MS, we understand the challenges you’re facing. Our comprehensive maintenance programs

and established technician network help ensure your critical systems receive the attention they

need, when they need it. Contact us today to discuss how we can help protect your operations from

the impacts of the skilled trades shortage.