The phone rings at 2 PM on a Tuesday. Your HVAC system just went down in the middle of winter,

and you need a technician: now. But instead of scheduling same-day service, you’re told the earliest

available appointment is three weeks out. Welcome to the new reality of the skilled trades shortage.

What started as a labor challenge has evolved into a full-blown crisis that’s fundamentally reshaping

how businesses operate across every industry. From delayed construction projects to emergency repairs

that stretch for weeks, the shortage of skilled trade workers isn’t just inconveniencing individual

businesses: it’s creating a domino effect that’s forcing entire industries to rethink their strategies.

The Numbers Don’t Lie: A Crisis in Scale

The skilled trades shortage isn’t just a minor hiccup: it’s a massive disruption affecting millions of

workers and countless businesses. The numbers paint a stark picture:

- Electricians: Short over 80,000 workers nationwide

- HVAC Technicians: Facing a deficit of approximately 115,000 workers

- Plumbers: Missing over 175,000 workers from their ranks

- Construction Overall: Needs 439,000 new workers in 2025 alone, with 1.9 million required over

the next decade

Here’s the demographic reality driving this crisis: 40% of the 12 million people in skilled trades are

over 45 years old, with nearly half of those workers over 55. Meanwhile, less than 9% of workers aged

19-24 are entering these fields. We’re watching experienced professionals retire faster than young talent

can replace them.

The Immediate Business Impact: When “Emergency” Becomes

“Eventually”

Project Delays Are the New Normal

Construction timelines that once took months now stretch into years. Contractors regularly turn down

profitable projects simply because they lack the workforce to complete them. Roads sit half-finished,

commercial buildings remain incomplete, and critical infrastructure upgrades get pushed to “sometime

next year.”

For businesses depending on timely project completion, this creates cascading problems. Retail

stores can’t open on schedule, manufacturers face delayed facility expansions, and property managers

deal with increasingly frustrated tenants.

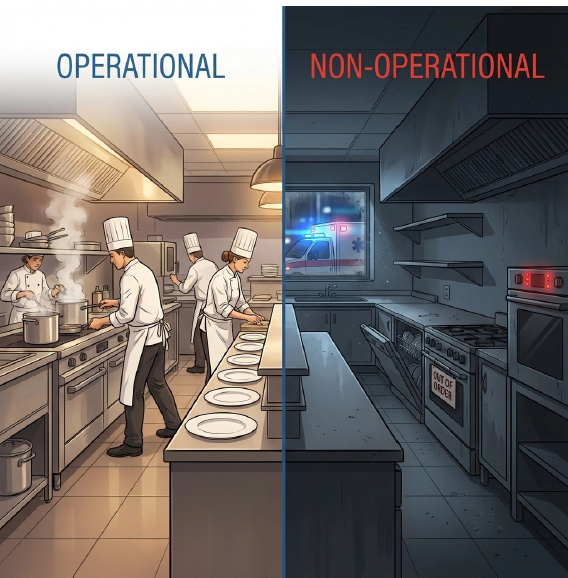

Emergency Services That Aren’t So Emergency

When your commercial refrigeration system fails on a Friday evening, losing thousands of dollars in

inventory, waiting three weeks for repair isn’t just inconvenient: it’s potentially business-ending. The

shortage has transformed true emergency services into scheduled appointments, forcing businesses

to plan for failures they can’t predict.

The Price of Scarcity

Labor costs have skyrocketed as companies compete for available workers. Signing bonuses between

$5,000 and $15,000 are now common just to attract candidates. Electricians command $65,000 to

$130,000 annually, HVAC technicians earn $65,000 to $120,000, and experienced plumbers make

$55,000 to $120,000 or more.

These increased labor costs don’t disappear: they get passed directly to customers through higher

service rates and project bids.

The Ripple Effect: How Every Industry Feels the Impact

Healthcare Facilities

Hospitals and medical centers can’t afford HVAC downtime or delayed fire safety system installations.

When trades shortages delay critical infrastructure work, patient care and regulatory compliance suffer.

One delayed sprinkler system installation can postpone a wing opening, affecting patient capacity

and revenue.

Food Service and Hospitality

Restaurants depend on functioning kitchen equipment, proper ventilation, and reliable refrigeration.

When repairs take weeks instead of days, food spoilage increases, health department violations multiply,

and customer satisfaction plummets. Hotels face similar challenges with room availability and

guest experience.

Manufacturing and Distribution

Production facilities require continuous operation of HVAC systems, electrical infrastructure, and specialized

equipment. Extended downtime for repairs that once took days now taking weeks can halt

entire production lines, affecting supply chains and customer deliveries.

Retail and Commercial Real Estate

Store openings get delayed, tenant improvements drag on for months, and basic maintenance becomes

a scheduling nightmare. Property managers juggle frustrated tenants while struggling to

maintain building systems that require specialized expertise.

How Smart Businesses Are Adapting

Forward-thinking companies aren’t just waiting for the shortage to resolve: they’re developing new

strategies to manage in this environment:

Preventive Maintenance Partnerships

Rather than hoping for emergency availability, businesses are investing heavily in preventive maintenance

contracts. Regular inspections and proactive repairs help avoid the crisis situations that now

take weeks to resolve.

Equipment Redundancy

Companies are installing backup systems and redundant equipment to minimize the impact of extended

repair timelines. While this increases upfront costs, it provides crucial operational continuity.

In-House Training Programs

Some larger organizations are developing internal capability for basic maintenance and repairs, reducing

their dependence on external contractors for routine tasks.

Strategic Vendor Relationships

Businesses are forming closer partnerships with trusted contractors, often paying premium rates for

priority service guarantees. These relationships provide some protection against the worst impacts of

the shortage.

The Technology Response: Innovation Born from Necessity

The shortage is accelerating adoption of new technologies designed to reduce labor dependency:

- Smart Building Systems that can diagnose problems remotely and prevent failures

- Predictive Maintenance Software that identifies issues before they become emergencies

- Automation Tools that handle routine tasks traditionally requiring skilled technicians

While technology can’t fully replace skilled trades, it’s helping businesses become more efficient with

the limited talent available.

Long-Term Implications: A Permanent Shift

This shortage isn’t a temporary blip: it represents a fundamental shift in how trades work gets done.

The Bureau of Labor Statistics projects 4% to 60% growth in skilled trades through 2033, depending

on the specific role. This growth assumes we can solve the shortage through increased recruitment,

but current trends suggest otherwise.

Pricing Structures Are Permanently Changed

Higher labor costs are becoming the baseline, not the exception. Businesses need to budget for significantly

higher service costs as the new normal.

Service Expectations Must Adjust

The days of same-day or next-day service for non-critical issues are largely over. Businesses must plan

further ahead and build longer lead times into their operations.

Preventive Strategies Become Essential

With emergency repairs taking weeks, preventing problems becomes far more critical than fixing

them quickly. This shift favors businesses that invest in quality equipment and regular maintenance.

What This Means for Your Business

The skilled trades shortage affects every business, whether you realize it or not. From the HVAC system

keeping your employees comfortable to the fire safety systems protecting your assets, these

trades are the invisible foundation supporting modern business operations.

The companies that thrive in this environment will be those that adapt their expectations, invest in

preventive strategies, and build strong relationships with reliable contractors. Those that continue operating

under pre-shortage assumptions: expecting immediate availability and low costs: will face increasing

operational disruptions.

At Pronto MS, we understand how critical these services are to your business continuity. While we

can’t solve the industry-wide shortage, we can help you navigate it through strategic planning, preventive

maintenance programs, and priority service relationships.

Ready to protect your business from trades shortage disruptions? Contact our team to discuss

how preventive maintenance and strategic planning can keep your operations running smoothly,

even in today’s challenging environment. Don’t wait for an emergency to discover how long repairs

now take: plan ahead and stay operational.

The skilled trades shortage is reshaping business as usual. The question isn’t whether it will affect

your operations: it’s whether you’ll be prepared when it does.